We can make it happen...

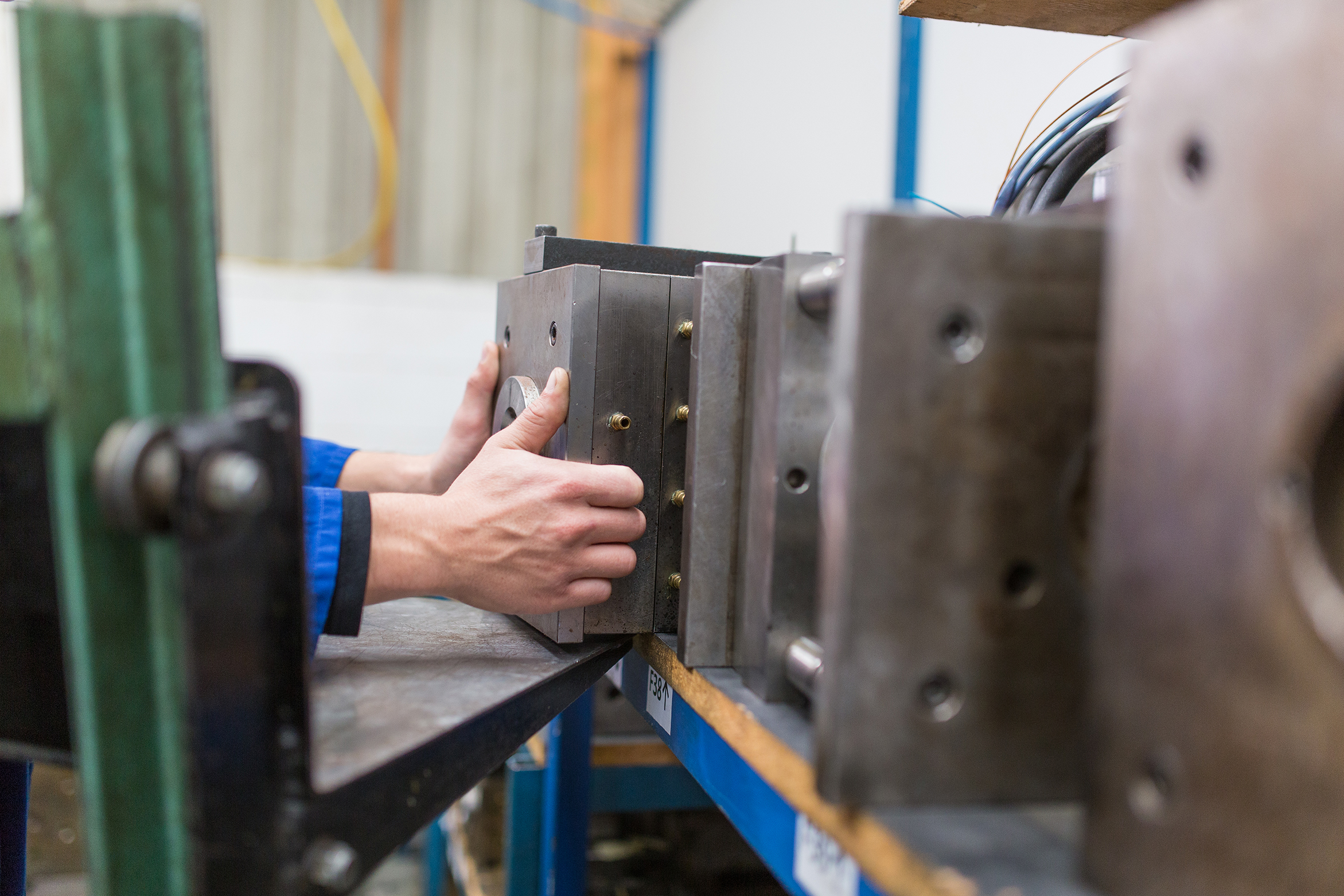

With 40 plus years experience in the industry we have an in-depth knowledge of what works, and what doesn’t. Our toolroom staff are trained in all areas of the plastic moulding process to ensure that there is an expert eye on your product at all stages.

The plastic industry is fast paced and always changing; this demands that we have the most accurate and reliable tooling for our clients needs.

Our toolroom has the latest equipment which includes three of the latest Haas CNC milling machines as well as the latest CNC lathe for turning, as well as surface grinding and spark eroding equipment. All are designed to ensure that each plastic component is as intricate and complex as it needs to be.

Our Toolroom Equipment

CNC Milling

CNC Turning

Surface grinding

Spark Eroding

Welding

Large Scale Radial Drilling

Tooling Services

Repairs

Manufacturing

Development

Design

Testimonials

Smart Parking

"He [Active Plastics] is very experienced in tool making and will help design the product so that he can build reliable tools for it... I would have no hesitation in recommending Bart and his people for both toolmaking and production.

— Roly Rogers, Head of Research & Development, Smart Parking Technology Ltd

Electrix

Active Plastics were able to complete, with very tight deadlines, the manufacturing of moulds and final production of 300 completed catenary roller blocks for Electrix to use in critical trials on the New Zealand National Electricity Grid in March 2016.

— Phil Patrick | Capital Works Manager | Electrix.